Sphérotène® (spherical fused tungsten carbide), is the main component of our hardfacing products.

Manufactured in France since 1986 by Technogenia , using an unique, innovative and patented process known as “cold crucible”

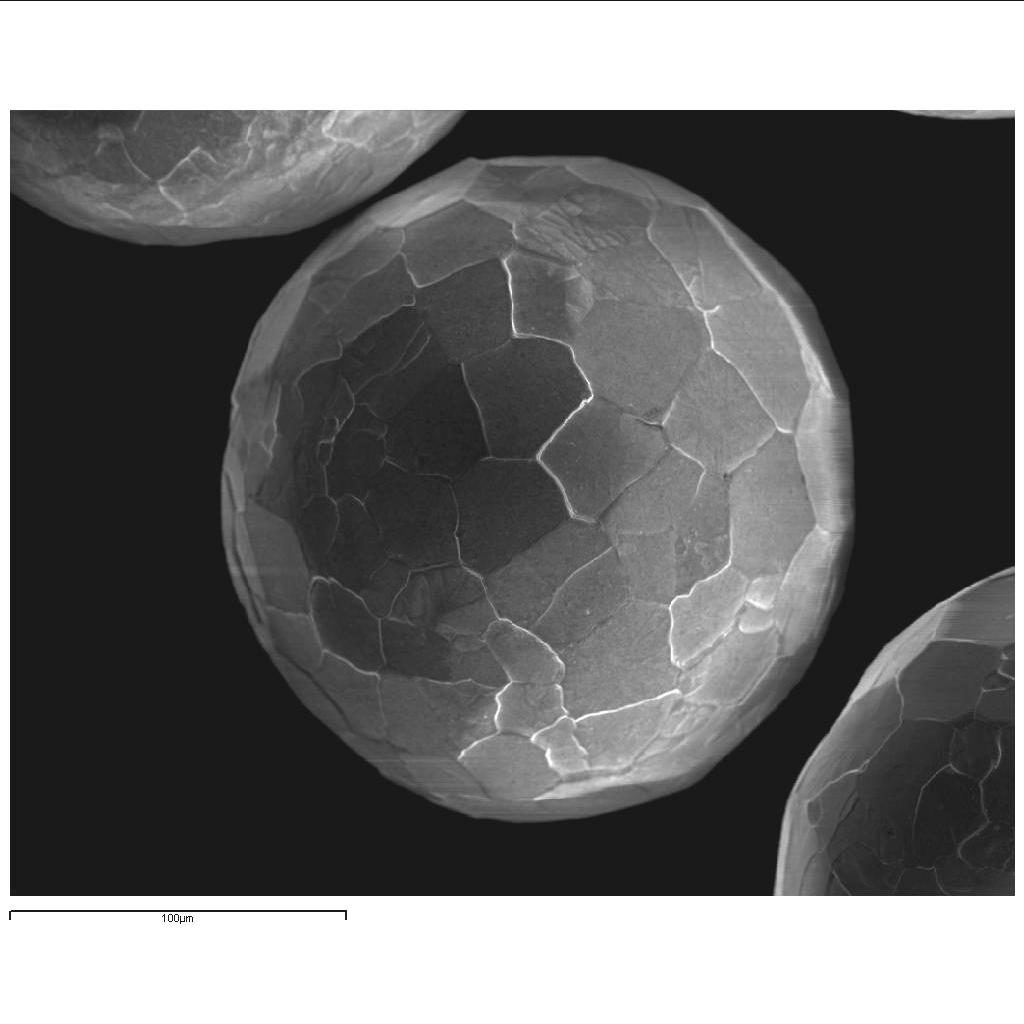

Spherotene® is obtained by spraying a liquid phase of tungsten carbide.

Spherotene® cast tungsten carbide spheres have hardness up to 3500 HV (Hardness Vickers) due to its very fine metallurgical structure know as “tangled needles”.

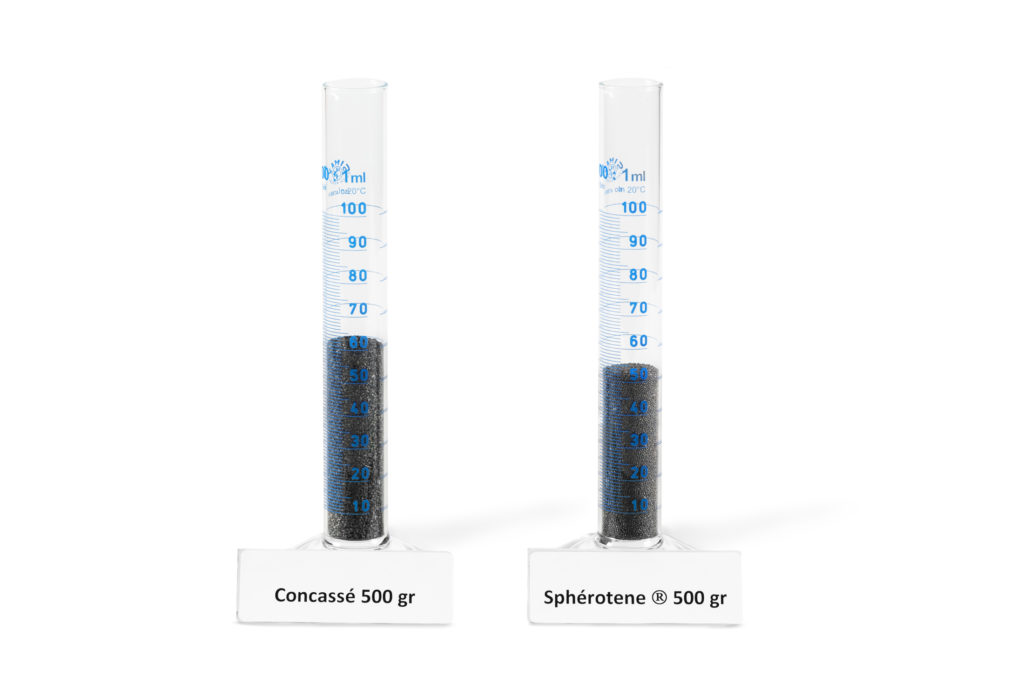

Due to the spherical shape of the tungsten carbide grains, the welding overlay has a much improved impact resistance and wear resistance than crushed tungsten carbide grains.

Sharp corners of crushed tungsten carbide tend to concentrate stress and lead to crack propagation (corner effect ). Spherotene® avoids this problem.

Spherotene® comes in grain sizes ranging from 40 µ to 2400 µm.

It is used in various welding products offered by Technogenia :

- Technosphere® welding rope.

- Torch powder

- Technolase® lasercladding powders

- PTA powders

- Technocore Cored wire

- Wear parts manufactured with Technocasting® process.

It is essential product for users of wear parts that are subjected to severe conditions of abrasion, in particular drilling equipment manufacturers.